If you’re looking to elevate your metal art projects, choosing the right CNC plasma table is essential. With precision, efficiency, and user-friendly features, these machines can transform your creative ideas into stunning reality. From the Eastwood Versa-Cut to the YESWELDER multifunctional cutter, each option offers unique benefits tailored for artists like you. Curious about which models stand out and what aspects to evaluate? Let’s explore the top contenders together.

Eastwood Versa-Cut 4X4 CNC Plasma Table with 40A Plasma Cutter

If you’re a metal artist or a hobbyist looking to elevate your craftsmanship, the Eastwood Versa-Cut 4X4 CNC Plasma Table with its 40A plasma cutter is your go-to tool. This all-in-one system offers a generous 49” x 43” cutting area, perfect for precision metal fabrication. Its user-friendly interface, featuring an intuitive LCD display, lets you access preloaded designs or upload custom CNC files effortlessly. With a cutting accuracy of ±0.5mm and the ability to handle materials up to 3/8” thick, you’ll experience unmatched control. Plus, Eastwood’s lifetime tech support guarantees you’ll never be left in the dark.

Best For: Metal artists and hobbyists seeking a versatile and precise CNC plasma cutting solution for their projects.

Pros:

- User-friendly interface with an intuitive LCD display for easy operation, ideal for beginners.

- Large cutting area of 49” x 43” accommodates various materials, enhancing versatility in projects.

- Lifetime tech support from Eastwood ensures assistance and guidance whenever needed.

Cons:

- Some users have reported concerns over customer service responsiveness.

- The cost of consumables may be considered high by some customers.

- The overall weight of the table (330 lbs) could make it difficult to move without assistance.

Eastwood Versa-Cut CNC Plasma Table

The Eastwood Versa-Cut CNC Plasma Table is an excellent choice for both hobbyists and professionals aiming for precision in metal design. With a 24-in. x 24-in. cut area, it’s perfect for creating custom brackets, sign art, and intricate shapes. The intuitive LCD touch screen controller makes operation seamless, so you won’t need an external computer. Its robust stepper motors guarantee accurate cutting, while adjustable torch travel allows for detailed work. Plus, you’ll appreciate the lifetime tech support and a 1-year warranty, providing peace of mind as you release your creative potential with this reliable and innovative tool.

Best For: Hobbyists and professionals seeking precision and ease in metal cutting design.

Pros:

- User-friendly with an intuitive LCD touch screen controller, eliminating the need for external devices.

- Accurate cutting performance ensured by robust stepper motors and adjustable torch travel for intricate designs.

- Lifetime tech support and a 1-year warranty provide peace of mind and assistance.

Cons:

- Limited cut area of 24-in. x 24-in. may not suffice for larger projects.

- Requires a compatible plasma cutter (Eastwood Versa-Cut 40) which is sold separately.

- Potential learning curve for beginners unfamiliar with CNC technology despite user-friendly features.

Eastwood Versa-Cut 4X4 CNC Plasma Table

For artists and hobbyists seeking a blend of affordability and professional-grade features, the Eastwood Versa-Cut 4X4 CNC Plasma Table stands out as an ideal choice. This table combines user-friendly operation with robust technology, featuring an intuitive LCD touch screen and a 33-gallon waterbed for efficient metal cutting. Its preloaded shapes and USB compatibility make it easy to upload custom designs. With precise movements powered by stepper motors, you’ll achieve accurate results every time. Plus, Eastwood’s commitment to quality and lifetime tech support guarantees you’ll have assistance whenever you need it. Enjoy a seamless cutting experience with this reliable machine!

Best For: Artists and hobbyists looking for an affordable CNC plasma table with professional features for precise metal cutting.

Pros:

- User-friendly operation with an intuitive LCD touch screen and preloaded shapes for easy design.

- Robust stepper motors ensure accurate cutting movements for high-quality results.

- Lifetime technical support from Eastwood provides assistance and enhances the customer experience.

Cons:

- Some users have reported challenges with customer service response times.

- Control panel placement during assembly may pose difficulties for some users.

- Limited cutting area compared to larger professional-grade plasma tables.

32 H x 21 W x 30 L Plasma Cutting Table

Engineered for both hobbyists and professionals, the 32 H x 21 W x 30 L Plasma Cutting Table from Quaintfab offers a sturdy carbon steel construction that guarantees durability during your art metalwork projects. Weighing 21.52 kg, it supports up to 250 lbs, making it perfect for heavy plate steel. The table features a slag catch tray, ensuring a clean workspace, while its ideal cutting height enhances your comfort. With 23 replaceable slats, you can easily maintain functionality. Customers praise its ease of assembly and sturdiness, although some suggest adding wheels for mobility. Overall, it’s a robust choice for all your plasma cutting needs.

Best For: Hobbyists and professionals who need a durable and reliable plasma cutting table for metalwork projects.

Pros:

- Sturdy carbon steel construction ensures long-lasting durability.

- Slag catch tray keeps the workspace clean and organized.

- Easy assembly process, making it user-friendly for all skill levels.

Cons:

- Some users suggest adding wheels for improved mobility.

- Concerns about powder-coated legs and slat durability have been noted.

- The package may be heavy upon arrival, which could be a challenge for some.

32 H x 21 W x 30 L Plasma Cutting Table

With a load capacity of 250 lbs, the 32 H x 21 W x 30 L Plasma Cutting Table is an ideal choice for both hobbyists and professionals tackling heavy plate steel projects. Constructed from sturdy carbon steel, it guarantees durability while featuring a slag catch tray to keep your workspace clean. The best cutting height enhances comfort during use, and the 23 replaceable slats can be turned over for extended life. Users appreciate its ease of assembly, sturdy design, and overall performance, although some suggest adding wheels for mobility. This table combines functionality and value, making it a reliable addition to your workshop.

Best For: The 32 H x 21 W x 30 L Plasma Cutting Table is best for hobbyists and professionals working with heavy plate steel projects.

Pros:

- Sturdy construction from carbon steel ensures long-lasting durability.

- Slag catch tray helps maintain a clean workspace by preventing debris from falling.

- Easy assembly process reported by users, enhancing user experience right out of the box.

Cons:

- Some users recommend adding wheels for improved mobility.

- Concerns regarding the durability of powder-coated legs and slats have been noted.

- A few customers suggested additional features like a slag funnel for better functionality.

Plasma Green 1050 Plasma Table Additive

Plasma Green 1050 Plasma Table Additive stands out as an essential solution for artists and metalworkers who want to keep their CNC plasma tables in top condition. This vibrant green additive protects against rust and biological growth, ensuring longevity and peak performance. You’ll use it at a 5% dilution or a 20:1 ratio, and it’s compatible with all types of steel. It’s non-toxic and bio-safe, so you won’t have to worry about harmful residues. Sold globally for over 10 years, Plasma Green 1050 is perfect for everything from personal projects to industrial applications. Keep your equipment running smoothly!

Best For: Plasma Green 1050 Plasma Table Additive is best for artists, metalworkers, and anyone using CNC plasma tables who want to protect their equipment from rust and biological growth.

Pros:

- Non-toxic and bio-safe: Safe for users and the environment without harmful residues.

- Long-lasting protection: Effectively prevents rust and biological growth, ensuring the longevity of cutting tables.

- Versatile application: Compatible with all types of steel, making it suitable for a variety of projects.

Cons:

- Requires dilution: Needs to be mixed at a specific ratio, which may be inconvenient for some users.

- Color may stain: The vibrant green color could potentially stain surfaces if spilled.

- Limited to plasma tables: Specifically designed for plasma tables, which may not be useful for users of other cutting technologies.

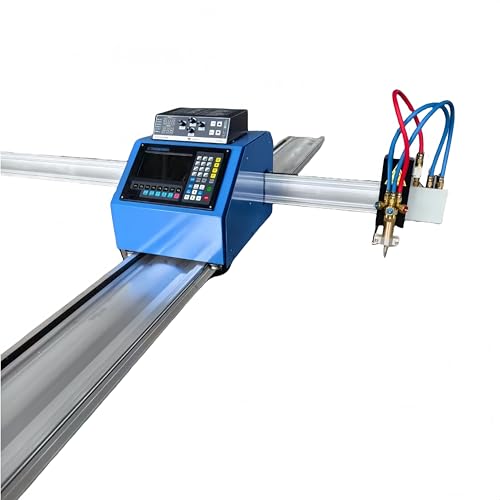

Portable CNC Machine with THC for Oxyfuel and Plasma Cutting

If you’re a metal artist or fabricator seeking versatility in your cutting capabilities, the Portable CNC Machine with THC for Oxyfuel and Plasma Cutting stands out as an ideal choice. Weighing just 188.6 pounds, it’s easy to transport, yet offers a robust cutting range of 59×98 inches. With automatic torch height control and a maximum plasma cutting speed of 138 inches per minute, it guarantees precision and efficiency. The included StarCAM software simplifies operation, making it accessible even for beginners. Plus, with a 2-year warranty and responsive customer support, you can confidently release your creativity with this powerful tool.

Best For: Metal artists and fabricators looking for a portable and versatile cutting solution.

Pros:

- High cutting speed: Achieves plasma cutting speeds of up to 138 inches per minute, enhancing productivity.

- Automatic torch height control: Ensures consistent cutting quality and precision across various materials.

- User-friendly software: The included StarCAM software simplifies operation for both beginners and experienced users.

Cons:

- Learning curve: Some users may experience challenges with the software and machine setup initially.

- Plasma equipment not included: Requires separate purchase of plasma equipment and torches, adding to the overall cost.

- Weight: At 188.6 pounds, it may still be cumbersome for some users to transport despite being labeled as portable.

Eastwood Versa-Cut CNC Plasma Table with 40A Plasma Cutter

The Eastwood Versa-Cut CNC Plasma Table, equipped with a powerful 40A plasma cutter, is an ideal choice for metalworking enthusiasts who value precision and ease of use. This all-in-one system supports dual voltage and can handle materials up to 3/8-inch thick. The intuitive LCD controller allows you to easily navigate preloaded patterns or upload your custom designs via USB. With a cutting accuracy of ±0.5mm, you’ll achieve impressive results. Although assembly can be tricky, the lifetime tech support guarantees you’re never alone. For both beginners and hobbyists, this table is a fantastic tool to release your creativity.

Best For: Metalworking enthusiasts and hobbyists looking for a user-friendly CNC plasma cutting solution with precision and versatility.

Pros:

- User-friendly interface with an intuitive LCD controller for easy navigation and operation.

- Versatile cutting capabilities with a maximum material thickness of 3/8-inch and dual voltage support.

- Lifetime tech support and a 1-year limited warranty provide reassurance for users.

Cons:

- Assembly can be challenging due to unclear instructions and unmarked parts.

- Compatibility issues with commercially available CNC plasma cut files may limit user experience.

- Customer feedback indicates dissatisfaction with overall functionality and performance in certain scenarios.

Plasma Green 9010 Plasma Table Additive

For artists and metalworkers seeking to enhance the longevity of their CNC plasma tables, the Plasma Green 9010 Plasma Table Additive stands out as an essential solution. This vibrant green additive protects your cutting table from rust and biological growth, ensuring a clean workspace. You’ll easily dilute it to 5% by volume, covering a 100-gallon table with just a 5-gallon pail. Compatible with all types of steel and aluminum, it won’t leave any mineralized or powdery deposits. Plus, it’s non-hazardous and bio-safe, making it an environmentally friendly choice for various sectors worldwide.

Best For: Artists and metalworkers looking to extend the lifespan of their CNC plasma cutting tables.

Pros:

- Protects against rust and biological growth, ensuring a clean workspace.

- Easy to dilute at a 20:1 ratio, making it convenient to use.

- Non-toxic and bio-safe, making it safe for various environments.

Cons:

- Requires dilution, which may be an additional step for some users.

- Coverage is limited to 100 gallons per 5-gallon pail, which may not be sufficient for larger tables.

- May not be as effective in extreme environmental conditions without regular maintenance.

YESWELDER Multifunctional Plasma Cutter 4-In-1 Cutting Machine

Crafted for metalwork enthusiasts and professionals alike, the YESWELDER Multifunctional Plasma Cutter stands out with its impressive 60Amp capacity, making it a perfect choice for those tackling diverse cutting tasks. This 4-in-1 tool offers plate cutting, grid cutting, gouging, and marking, providing versatility for any project. With a clean cut capability of 5/16″ at 110V and 3/4″ at 220V, it excels in precision. The non-touch pilot arc technology enhances performance on rough surfaces, while the user-friendly digital display keeps you informed. Plus, its robust safety features guarantee both your safety and the cutter’s longevity. Release your creativity!

Best For: Metalwork enthusiasts and professionals seeking a versatile cutting solution for various projects.

Pros:

- Versatile 4-in-1 functionality for plate cutting, grid cutting, gouging, and marking.

- Non-touch pilot arc technology allows for cutting on rough or painted surfaces without direct contact.

- User-friendly digital display for real-time monitoring of air pressure, voltage, and current.

Cons:

- May require additional training for beginners to fully utilize its advanced features.

- Heavier than some portable options, which could affect mobility on job sites.

- Limited cutting thickness capabilities at lower voltage settings compared to higher voltage operations.

Factors to Consider When Choosing CNC Plasma Tables for Art Metalwork

When choosing a CNC plasma table for your art metalwork, you’ll want to evaluate several key factors. The cutting area size, user-friendly interface, and precision are essential for your projects. Additionally, think about the material thickness capacity and power requirements to guarantee the table meets your needs.

Cutting Area Size

Choosing the right cutting area size for your CNC plasma table is crucial for your art metalwork projects. A larger cutting area allows you to work with bigger materials and tackle more complex designs, which can elevate your creations. For medium-sized projects, a cutting area of 49” x 43” is ideal, offering enough space for various metal sheets without frequent repositioning. If you’re focusing on intricate designs, consider a smaller table, like a 24” x 24”, which suits detailed work. Remember, the thickness of your materials matters too; larger cuts need robust support for stability. A well-defined cutting area guarantees precision and accuracy, essential for achieving the best results in your artistic endeavors.

User-Friendly Interface

A cutting area size is just the beginning of what makes a CNC plasma table effective for art metalwork. You’ll want a user-friendly interface that features an intuitive LCD display, streamlining operations without needing external computers. Many models come preloaded with standard shapes and design patterns, letting you engage in projects without extensive programming knowledge. The ability to accept custom CNC files via USB also enhances accessibility, making it easy to import your own designs. With adjustable settings for torch travel and other parameters, you gain precise control over the cutting process. Overall, simplified navigation greatly reduces the learning curve, allowing you to achieve professional-quality results in metal art fabrication with ease.

Precision and Accuracy

Precision and accuracy are crucial elements in selecting CNC plasma tables for art metalwork. You’ll want to take into account models with movement accuracy of ±0.2mm, especially for intricate designs. Look for cutting accuracy, too; tables that achieve ±0.5mm cutting precision can greatly affect your artwork’s final appearance. A larger torch travel range—like 49.2 inches on the X-Axis and 43.3 inches on the Y-Axis—allows for extensive cuts and reduces the need to reposition materials, enhancing your creative workflow. Additionally, robust stepper motors guarantee smooth and accurate cutting, essential for detailed artwork. Don’t forget to maintain consistent voltage and current settings during operation; this will help you achieve clean edges and intricate patterns in your metalwork.

Material Thickness Capacity

When selecting a CNC plasma table for art metalwork, one key factor to take into account is its material thickness capacity. Typically, CNC plasma tables can handle materials ranging from 3/8 inches to 1 inch, depending on the plasma cutter’s power. Thicker materials require more powerful cutters and precise settings. It’s also essential to take into account the cutter’s duty cycle; this tells you how long you can cut before it needs to cool down, particularly important for thicker materials. Verify the cutter’s output current meets the needed thickness, usually between 15 to 40 Amps for standard machines. Finally, different metals may require specific settings to achieve clean cuts without excessive slag or burn-through, so understanding material types is crucial.

Power Requirements

Choosing a CNC plasma table for art metalwork means considering its power requirements, as these directly influence your cutting capabilities and efficiency. Most tables require specific voltage inputs, often available in 120V or 240V, which affects compatible plasma cutters. Additionally, the rated input current can vary; some tables need up to 27.4 Amps at 240V, so make certain your electrical supply meets this demand. The output current typically ranges from 15 to 40 Amps, impacting the thickness of materials you can cut. Don’t overlook duty cycle ratings, as they indicate how long your plasma cutter can run without overheating. Finally, many plasma cutters handle materials up to 3/8 inch thick, guiding your selection for specific art projects.

Software Compatibility

Selecting the right software compatibility for your CNC plasma table is essential, as it directly impacts your workflow and the quality of your art metalwork. Make sure the table supports popular design software formats like DXF or SVG, so you can easily import your artistic designs. Check if the CNC controller is compatible with specific software applications for smooth integration and operation. Look for tables that come with preloaded design patterns or allow custom CNC files via USB, enhancing your creative flexibility. Investigate whether the software includes features like nesting or layout optimization, which can minimize material waste during your projects. Finally, consider the availability of updates or support for the software, as this affects long-term usability and adaptation to new trends.

Support and Warranty

While evaluating CNC plasma tables for art metalwork, considering support and warranty options is essential to your investment’s longevity and performance. A longer warranty often reflects the manufacturer’s confidence in the product’s durability and quality. Typically, a limited warranty lasts about a year, covering defects and ensuring protection against early issues.

Additionally, many manufacturers offer lifetime tech support, which can be invaluable when you face operational challenges. Customer feedback shows how vital responsive support teams are for a smooth troubleshooting and maintenance experience. Finally, researching the company’s reputation for honoring warranties and providing satisfactory customer service can give you peace of mind, ensuring that your artistic journey remains uninterrupted and enjoyable.

Assembly and Setup

After ensuring you have reliable support and warranty options, the next step involves the assembly and setup of your CNC plasma table. Clarity in assembly instructions can vary, so check for unmarked parts or unclear guidelines that might lead to frustration. Make sure all components are accounted for and properly labeled to streamline the process. Before starting, verify if you need any additional tools not included in the package. User feedback emphasizes the value of a detailed step-by-step assembly guide and access to online resources for troubleshooting. Finally, don’t neglect proper alignment and calibration after assembly; this is essential for achieving cutting accuracy, typically specified within ±0.2mm.