As you explore the world of CNC machining, you’ll find that the right vacuum table can make a significant difference in your workflow. In 2025, the top CNC vacuum tables will showcase advanced features that enhance precision and efficiency. From improved adsorption plates to powerful vacuum pumps, these tools are designed to meet your needs. Curious about which models stand out and what factors to evaluate? Let’s take a closer look.

SainSmart Genmitsu Vacuum Clamp Pod for CNC Router Accessory

If you’re a CNC enthusiast looking for a reliable way to secure both small and irregularly shaped workpieces, the SainSmart Genmitsu Vacuum Clamp Pod is an excellent choice. This aluminum CNC hold-down kit measures 4.7 x 4 x 0.6 inches and weighs just 1.17 pounds, making it easy to handle. It effectively grips materials like wood and metal, accommodating pieces from 24mm coins to 90mm blocks. With universal compatibility, it mounts effortlessly on MDF or T-slot tracks. Users appreciate its strong hold and quick setup, especially when paired with a good vacuum pump for ideal performance.

Best For: CNC enthusiasts looking for a reliable and versatile solution to secure small and irregularly shaped workpieces.

Pros:

- Strong Hold: Provides excellent gripping power for various materials, ensuring stability during CNC operations.

- Quick Setup: Easy to install and use, especially with compatible vacuum pumps, saving time on setup.

- Universal Compatibility: Works with a range of CNC machines and mounting surfaces, making it versatile for different projects.

Cons:

- Vacuum Pump Required: Needs a separate vacuum pump for operation, which adds to the overall cost and setup.

- Performance Varies: Hold down force can fluctuate depending on the vacuum pressure used, which may require adjustments.

- Limited Size Range: Designed primarily for smaller workpieces, which may not accommodate larger projects effectively.

SENCTRL Automatic Vacuum Switch for Power Tools

The SENCTRL Automatic Vacuum Switch is ideal for woodworkers and DIY enthusiasts who want to streamline their workflow by automating the operation of their vacuum systems. This innovative switch turns your vacuum on and off with your power tools, enhancing efficiency. You’ll appreciate features like Load Sensing Technology, which prevents overload, and a shut-off delay that clears debris after tool use. Built from durable materials, it’s compatible with various tools, ensuring versatility. While some users report occasional compatibility issues, many praise its functionality and customer support. Just keep in mind the cord length and consider using extension cords for convenience.

Best For: Woodworkers and DIY enthusiasts looking to automate their vacuum systems for improved efficiency.

Pros:

- Convenient automation: Automatically turns the vacuum on/off with power tools, enhancing workflow.

- Load Sensing Technology: Prevents circuit overload, ensuring safe operation of tools.

- Durable construction: Made with flame-retardant materials and a robust power cord for longevity.

Cons:

- Compatibility issues: Some users report unexpected shutdowns with specific tools, affecting reliability.

- Short power cord: The 19.7-inch cord may require extension cords for convenience.

- Longevity concerns: Reports of switch failures after a few months of use, leading to disappointment.

Dust Collection Boom Arm for CNC Router

For makers and hobbyists seeking to optimize their workspace, the Dust Collection Boom Arm for CNC Routers is an essential tool. This adjustable clamp mount hose holder quickly attaches to your CNC workbench without tools, keeping your dust hose off the work area. Its flexible positioning prevents hose sag, protecting your CNC’s motion paths and ensuring smooth operation. The Velcro hose strap accommodates hoses from 1.25 to 2.5 inches, making it ideal for compact CNC setups. By suspending the dust hose, you maintain an unobstructed workspace, enhancing airflow and improving overall efficiency in your projects.

Best For: Makers and hobbyists looking to optimize their CNC workspace by keeping dust hoses organized and out of the way.

Pros:

- Easy clamp-on installation requires no tools or drilling, allowing for quick setup.

- Adjustable boom arm effectively keeps the dust hose off the work area, preventing interference with moving parts.

- Compatible with a variety of hose sizes (1.25 to 2.5 inches), making it versatile for different setups.

Cons:

- May not be suitable for larger CNC machines that require more robust hose management solutions.

- The clamp may not provide a secure fit on very thick or uneven workbench edges.

- Limited to hose sizes specified; users with different hose diameters may need additional adapters.

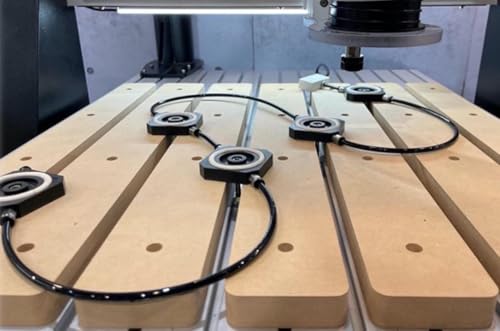

Vacuum Clamp Pod Kit for CNC Projects

Engineered specifically for CNC enthusiasts and professionals, the Vacuum Clamp Pod Kit enhances your machining experience by providing secure workpiece hold-down without obstructing access. This kit includes two pods, T-bolts, knobs, and a polyurethane vacuum hose, making it easy to set up. Designed for use with a vacuum pump, it allows rapid clamping and release, perfect for production projects. While users appreciate its effectiveness, some report challenges with uneven surfaces and vacuum strength. For ideal stability, consider using three pods. With a 30-day return policy, you can confidently test this modern solution in your workshop.

Best For: CNC enthusiasts and professionals looking for a reliable clamping solution that provides unobstructed access to workpieces.

Pros:

- Quick clamping and release mechanism ideal for production-type projects.

- Compatible with various mounting options including T-track and slotted CNC tables.

- Lightweight design with no arm clamps allows for unobstructed machining.

Cons:

- Effectiveness may be limited on uneven surfaces, affecting vacuum seal integrity.

- Some users report vacuum strength issues, especially when using multiple pods.

- Optimal stability often requires the use of three pods instead of four.

LAGUNA CNC ROUTER CREATOR VACUUM HOLD DOWN KIT

Achieving precision in your CNC projects becomes effortless with the Laguna CNC Router Creator Vacuum Hold Down Kit. This lightweight, compact kit features phenolic resin vacuum pods, each with its own seal, ensuring your materials stay firmly in place. You can easily mount the pods on an MDF spoil board or an aluminum table using the included screws. The 1/4″ hose connects seamlessly to the vacuum port, allowing for customization in length. Plus, there’s no need for batteries—just hand-operated convenience. With a 30-day return guarantee, you’ll feel confident in your investment for enhanced efficiency and accuracy.

Best For: The Laguna CNC Router Creator Vacuum Hold Down Kit is best for woodworkers and CNC enthusiasts looking for a reliable solution to securely hold materials during machining.

Pros:

- Compact and lightweight design makes it easy to handle and store.

- Customizable hose length allows for flexible setup based on project requirements.

- Easy installation on MDF or aluminum surfaces with included screws.

Cons:

- Hand-operated mechanism may not be as convenient for larger projects requiring frequent adjustments.

- Plastic construction may not be as durable as metal alternatives in high-demand environments.

- Limited to vacuum hold down; may not suit applications requiring other types of clamping.

CNC Vacuum Chuck Fixture Plate for Machining Center

The CNC Vacuum Chuck Fixture Plate is an ideal solution for machinists and fabricators who seek precision in workpiece clamping without the hassle of additional tools or materials. Measuring 300 x 400mm, it fits machining centers, lathes, and milling machines. The upgraded Rapid Adsorption Plate eliminates the need for sealing strips or glue, ensuring quick workpiece fixation. Its 234 separately designed adsorption holes prevent metal chip blockage, accommodating materials like stainless steel, wood, and PVC. For top performance, use a vacuum pump of 7 CFM/200 LPM or larger. This fixture plate simplifies your workflow while enhancing accuracy and efficiency.

Best For: Machinists and fabricators seeking efficient and precise workpiece clamping solutions without the need for additional tools.

Pros:

- Upgraded Rapid Adsorption Plate allows for quick and easy workpiece fixation.

- Versatile Compatibility with various materials such as stainless steel, wood, and PVC.

- Efficient Design featuring 234 adsorption holes that prevent metal chip blockage.

Cons:

- Requires a vacuum pump of 7 CFM/200 LPM or larger for optimal performance.

- Limited to workpieces with a base size larger than 10 x 10 cm.

- Not suitable for workpieces outside the recommended height range of 3 – 25 mm.

WEN Woodworking Dust Collector (DC3401)

For woodworkers looking to maintain a clean and efficient workspace, the WEN Woodworking Dust Collector (DC3401) stands out with its impressive 660 CFM airflow. This compact unit features a 5.7-amp brushed motor, ensuring powerful suction comparable to higher horsepower shop vacs. Weighing only 17 pounds, it’s easy to transport and store. The 12-gallon, 5-micron zippered collection bag effectively captures dust, while the 4-inch inlet connects seamlessly to your tools. With lockable swivel casters and optional wall mounting, you’ll enjoy flexibility and stability. Rated 4.2 stars, it’s a favorite among home workshop enthusiasts for its efficiency and reliability.

Best For: Woodworkers seeking a compact and efficient dust collection solution for home workshops.

Pros:

- Powerful Performance: Delivers 660 CFM airflow, providing effective dust collection comparable to higher horsepower shop vacs.

- Mobility and Storage: Lightweight design with lockable swivel casters and optional wall mount for easy transport and space-saving storage.

- User-Friendly Maintenance: Easy-access carbon brush caps simplify routine upkeep for long-term efficiency.

Cons:

- Suction Concerns: Some users report issues with low suction power under certain conditions.

- Noise Level: While quieter than traditional shop vacs, it may still produce noise that some users find bothersome.

- Packaging Issues: A few customers experienced problems with product condition upon arrival, indicating potential packaging concerns.

Milescraft 1501 Dust Router – Complete Dust Collection System for Router Tables

Designed with versatility in mind, the Milescraft 1501 Dust Router is an ideal solution for woodworkers seeking a complete dust collection system for their router tables. It easily attaches to most router tables, making it suitable for both permanent and temporary setups. Verify your router base or lift has an opening of 3-3/8” or larger for maximum compatibility. The system connects to your vacuum source via a 1-1/2″ hose, effectively capturing dust and debris. With a flexible silicone dust cup and a reliable hook and loop attachment, you’ll enjoy cleaner workspaces and improved efficiency during your projects.

Best For: Woodworkers looking for a complete dust collection solution for their router tables that offers versatility and ease of use.

Pros:

- Easily attaches to most router tables for both permanent and temporary setups.

- Effective dust capture with a 1-1/2″ hose compatible with workshop vacuums and dust collectors.

- Flexible silicone dust cup with hook and loop attachment ensures a cleaner workspace.

Cons:

- Requires a router base or lift with an opening of 3-3/8” or larger for compatibility.

- Adhesive hook and loop attachment may struggle on multi-surface geometries.

- May not fit all router models without modifications.

A3 Desktop Vacuum Forming Machine for Prototypes and Molds

Perfect for educators and hobbyists alike, the A3 Desktop Vacuum Forming Machine revolutionizes prototype creation and mold-making. This compact machine, measuring 297mm x 420mm, allows you to produce molds directly in your classroom or kitchen. With its rugged aluminum and iron design, it fits seamlessly into any workspace. You can create products using various materials, including laser-cut items and even natural objects like scallop shells. The user-friendly interface lets you easily adjust temperature and heating time, ensuring precise results every time. Just plug it in, and you’re ready to start crafting your next project without any hassle.

Best For: Educators and hobbyists looking to create prototypes and molds conveniently in their own workspace.

Pros:

- User-friendly interface allows for easy adjustments to temperature and heating time.

- Compact design fits seamlessly into any workspace without needing external devices.

- Versatile material compatibility enables the use of various materials, including natural objects and laser-cut items.

Cons:

- Limited size may restrict larger projects or molds.

- Requires some experience to achieve optimal results, particularly with temperature adjustments.

- Initial setup may take time for beginners to familiarize themselves with the machine’s functions.

Dust Collector for CNC Machine, 2.8L Dust Extraction System

A powerful suction capability of 6,000 Pa makes the Dust Collector for CNC Machine an excellent choice for hobbyists and professionals working with desktop CNC equipment. Weighing just 4.29 pounds, its compact design fits seamlessly into your workspace. The 2.8L dust capacity and transparent bin allow for easy debris disposal. With a motor speed of 50,000 rpm, you’ll appreciate its efficiency. Plus, the built-in filter pad and negative ion generator keep the air clean. Safety features, like overheat protection and auto start/stop, enhance your experience, making it a reliable tool for maintaining a tidy and safe working environment.

Best For: Hobbyists and professionals working with desktop CNC machines looking for an effective dust extraction solution.

Pros:

- Powerful suction of 6,000 Pa ensures efficient dust collection.

- Compact and lightweight design makes it easy to fit into any workspace.

- Safety features such as overheat protection and auto start/stop enhance user experience.

Cons:

- Some users have reported issues with the auto function not activating with CNC spindles.

- Not portable, as it is designed for indoor use only.

- Limited to 3 power levels, which may not suit all user preferences.

Factors to Consider When Choosing CNC Vacuum Tables

When you’re choosing a CNC vacuum table, consider key factors that impact your workflow. Think about the size of your workpieces, the vacuum power you need, and the types of materials you’ll be using. Don’t forget to evaluate the installation flexibility and the overall design for durability.

Workpiece Size Compatibility

Choosing the right CNC vacuum table hinges on understanding the size compatibility of your workpieces. Make sure the table can accommodate your workpiece dimensions, especially if it’s optimized for specific thicknesses, like 24mm to 90mm. If you’re working with irregular shapes, select a table that maintains a secure hold on flat contact areas, regardless of shape. The maximum hold down force is also essential; some systems can achieve up to 50 lbs with a quality vacuum pump. Check for material compatibility too—your vacuum table should handle wood, acrylic, plastic, and metal for versatility. Finally, evaluate mounting options; compatibility with T-track or slotted CNC tables can ease installation and adjustments for different workpiece sizes.

Vacuum Power Requirements

Vacuum power requirements play an essential role in guaranteeing your CNC vacuum table performs effectively. The size and weight of your workpieces directly influence the vacuum strength needed, with effective holding forces typically ranging from 10-12 lbs for shop vacuums to up to 50 lbs for high-quality pumps. For ideal performance, a vacuum pump rated at 7 CFM or larger is perfect. Additionally, the type of material you’re machining can affect vacuum performance, especially with irregular or non-flat surfaces requiring stronger suction. The design of your vacuum table, including the number and size of vacuum pods, also impacts power distribution and stability. Finally, guarantee proper sealing and maintenance to avoid leaks that compromise vacuum strength.

Material Types Supported

Selecting the right CNC vacuum table involves understanding the variety of materials it can support. You’ll find that these tables work well with wood, acrylic, plastic, and metal, offering versatility for your machining projects. Keep in mind that the compatibility with irregularly shaped workpieces depends on the flatness of the contact area, which guarantees a secure hold. Some materials might need specific vacuum pressures to maintain an effective seal during machining. Additionally, consider the thickness and weight of your materials; heavier items typically require stronger vacuum forces. Understanding properties like porosity and surface texture is essential, as they greatly affect the vacuum hold’s effectiveness and the overall machining quality. Choose wisely to enhance your project outcomes.

Installation Flexibility and Ease

When considering installation flexibility and ease, it’s crucial to look for vacuum tables that offer clamp-on installation methods, enabling quick setups without tools or drilling. This feature enhances your ability to adapt to different workspace configurations effortlessly. Choose models compatible with T-tracks or slotted CNC tables, as they provide versatile mounting options for easier integration into existing setups. Adjustable boom arms or effective hose management systems keep hoses off your work area, ensuring unobstructed access and improved workflow during machining. Additionally, seek vacuum tables that allow for easy positioning and repositioning of workpieces, particularly for small or irregularly shaped materials. Finally, evaluate designs with quick activation and release mechanisms to facilitate rapid clamping changes, enhancing productivity in your projects.

Design and Durability

To guarantee your CNC vacuum table meets your needs, consider its design and durability as key factors. First, look at the construction material; high-quality materials like aluminum or phenolic resin provide enhanced durability and resistance to wear. A robust design with features such as vacuum seals and multiple mounting options prevents leaks and guarantees a secure hold on your workpieces. Make certain the vacuum table’s dimensions and weight capacity align with your intended projects to handle the materials safely. Adjustable features can also offer flexibility in positioning and compatibility with various CNC machines, boosting performance. Finally, check user feedback—products with high ratings for build quality often indicate a reliable investment for your CNC operations.

Maintenance and Cleaning

Maintaining your CNC vacuum table is crucial for guaranteeing consistent performance and longevity, so it’s important to establish a regular cleaning routine. Start by checking and replacing gaskets to guarantee ideal sealing and prevent vacuum loss during operations. Cleaning the vacuum pods and hose connections is essential to eliminate debris that can obstruct airflow and reduce suction power. Don’t forget to inspect and clean the vacuum pump filters periodically to maintain suction efficiency. Use a soft cloth or brush to clean the vacuum surface, preventing scratches and preserving the sealing area’s integrity. Finally, when you’re not using the table, store it properly and cover it to minimize dust accumulation, reducing the need for extensive maintenance.

Cost and Value

Regular maintenance of your CNC vacuum table guarantees peak performance, but understanding the cost and value is just as important when making a purchase. Initial investments can vary greatly, ranging from a few hundred to several thousand dollars based on size and features. When evaluating options, consider the long-term value by gauging durability and potential reductions in labor costs due to enhanced efficiency. Don’t forget maintenance costs; some tables may need replacement parts, which can add to your expenses. Investing in a higher-quality vacuum table can lead to substantial time savings and increased output. Finally, confirm compatibility with your existing CNC equipment to avoid additional costs from modifications or replacements.

Accessory Compatibility Options

When selecting a CNC vacuum table, compatibility with your existing equipment is essential for achieving ideal performance. First, verify the vacuum table matches your vacuum pump’s specifications, as certain pumps offer specific capabilities for peak operation. Look for adjustable or modular designs that integrate seamlessly with your CNC setup, particularly those featuring T-tracks or slotted tables. Check the mounting options like M6 screws or T-nuts to confirm they fit your CNC machine’s hardware. Evaluate the materials and sizes of included vacuum pods or clamps, verifying they can securely hold your workpieces, including irregular shapes. Finally, consider how well the vacuum table maintains a strong seal with various materials, such as wood, acrylic, and metal, to enhance efficiency.