When you’re looking to enhance your craft projects with flawless finishes, choosing the right resin curing station is essential. With so many options available, it can be overwhelming to find the perfect fit for your needs. From rapid drying times to user-friendly designs, these stations offer various features that cater to both beginners and seasoned pros. Let’s explore the top 10 resin curing stations that can elevate your crafting experience and help you achieve exceptional results.

ANYCUBIC Wash and Cure Station for 3D Printers

The ANYCUBIC Wash and Cure Station is the perfect choice for 3D printing enthusiasts looking for a compact, all-in-one solution for post-printing cleanup. This upgraded 2-in-1 station works seamlessly with the Mars Anycubic Photon Mono 4 2 resin printer. Its 4L cleaning bucket accommodates larger models, while the dual-layer basket offers adjustable heights for versatility. You’ll enjoy a quieter operation and enhanced curing efficiency with its innovative gooseneck light. Plus, the user-friendly interface makes switching between cleaning and curing modes a breeze. Overall, it’s designed to simplify your workflow and elevate your 3D printing experience.

Best For: 3D printing enthusiasts seeking a compact and efficient all-in-one solution for post-printing cleanup.

Pros:

- Combines washing and curing functions in one device for convenience.

- Enhanced curing efficiency with powerful UV LEDs for uniform results.

- Compact design saves space, replacing multiple machines.

Cons:

- Cannot use cleaning and curing functions simultaneously.

- Some users prefer ultrasonic cleaners for more thorough cleaning.

- Price point may be higher compared to DIY alternatives.

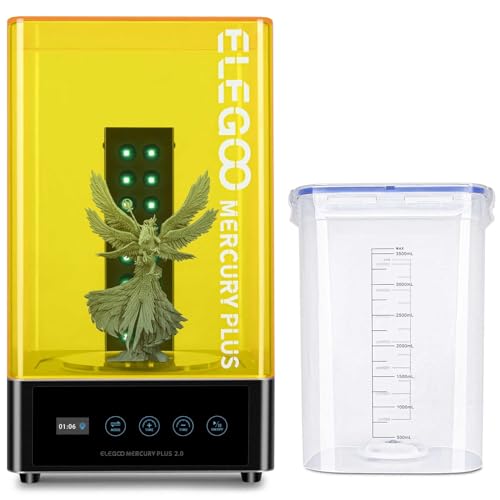

ELEGOO Mercury Plus 2.0 Wash and Cure Station V2 for 3D Printers

For enthusiasts of 3D printing, the ELEGOO Mercury Plus 2.0 Wash and Cure Station V2 stands out as the perfect choice, thanks to its intelligent curing and washing capabilities. Compatible with most LCD, DLP, and SLA 3D printers, including the ELEGOO Mars series, it effectively cleans and cures your resin prints. The station features an anti-UV lid, a fan-less curing mode, and a TFT screen for easy operation. With 16 UV LEDs and a rotating turntable, it guarantees uniform curing. Priced at $120, it’s a worthwhile investment for anyone looking to enhance their printing workflow and efficiency.

Best For: The ELEGOO Mercury Plus 2.0 Wash and Cure Station V2 is best for 3D printing enthusiasts looking for an efficient and effective solution to wash and cure their resin prints.

Pros:

- Intelligent curing and washing with a TFT screen for easy monitoring.

- Anti-UV lid and fan-less mode enhance user experience by reducing noise and UV exposure.

- Compatible with a wide range of resin types and 3D printer models, making it versatile.

Cons:

- Some users report durability issues with the plastic lid and wash bin compared to the metal body.

- Initial maintenance challenges and wash bin latch problems noted by users.

- A quieter button mechanism and a second container for improved workflow would be beneficial.

ANYCUBIC Wash and Cure Machine 3.0 for 3D Printers

Craft enthusiasts and 3D printing aficionados will find the ANYCUBIC Wash and Cure Machine 3.0 an invaluable tool for achieving pristine results. This 2-in-1 station effectively washes and cures resin prints up to 7.3 inches, enhancing uniformity and efficiency. With its innovative Flexicure Gooseneck Light Design, you’ll enjoy improved curing effects and energy output. The user-friendly interface allows you to switch between modes effortlessly, while the adjustable cleaning basket saves IPA. Despite some mixed reviews on quality control, most users praise its performance and customer support. Overall, it’s a reliable addition to your crafting arsenal.

Best For: Craft enthusiasts and 3D printing aficionados looking to achieve high-quality results with resin prints up to 7.3 inches.

Pros:

- User-friendly interface with one-click mode selection for easy operation.

- Enhanced curing and washing features improve the efficiency and quality of resin prints.

- Adjustable cleaning basket design allows for IPA savings and compatibility with various printer models.

Cons:

- Mixed reviews on quality control, with some users experiencing issues like detached control panels.

- Some users suggest the need for design improvements for better storage and handling of components.

- Decibel level may still be noticeable for those sensitive to noise, despite being relatively quiet.

3D Printer Resin Curing Station with UV Light

Looking for a compact solution to cure your resin prints quickly? The D Printer Resin Curing Station with UV Light offers an efficient way to get the job done. With dimensions of 8.27×8.67×10.24 inches, it fits models up to 10.1 inches and cures them in just 15 to 20 minutes. Assembly is straightforward, though you may face minor challenges aligning reflective stickers. The solar-powered rotating display and protective features keep your eyes safe from UV exposure. Plus, it’s budget-friendly compared to pricier alternatives, making it a solid choice for DIY enthusiasts looking to enhance their craft.

Best For: DIY enthusiasts and hobbyists looking for an economical and efficient solution to cure their resin prints quickly.

Pros:

- Cures models efficiently in just 15 to 20 minutes, saving time in your printing process.

- Compact design fits models up to 10.1 inches, making it suitable for smaller printers.

- Solar-powered rotating display enhances usability by eliminating the need for batteries.

Cons:

- Durability concerns due to the cardboard construction, which may not withstand heavy use.

- Size may be smaller than expected, leading to potential limitations for larger prints.

- Potential UV light escape through gaps, raising concerns about safety and effectiveness.

3D Printer UV Resin Curing Light with Solar Turntable 360° Rotating Stand

The 3D Printer UV Resin Curing Light with Solar Turntable 360° Rotating Stand is ideal for anyone engaged in SLA, DLP, or LCD 3D printing projects. It features six high-power 405nm UV LEDs that cure photosensitive resin prints efficiently, typically in just 10-15 seconds. For thicker parts, you may need to allow extra curing time. The solar turntable, operating on UV light or natural sunlight, rotates your prints for even exposure, supporting up to 500g. Remember to wear eye protection due to its strong UV output. With its compact design and high customer ratings, it’s a must-have for your 3D printing toolkit.

Best For: The 3D Printer UV Resin Curing Light is best for hobbyists and professionals engaged in SLA, DLP, or LCD 3D printing who require efficient resin curing.

Pros:

- Efficient Curing: Cures resin quickly in just 10-15 seconds, improving productivity.

- 360° Rotation: The solar turntable ensures even exposure for all sides of the print.

- Compact Design: Portable and lightweight, making it easy to integrate into any workspace.

Cons:

- Limited to Resin Printing: Not suitable for liquid resin or filament prints, restricting versatility.

- Requires Eye Protection: Strong UV output necessitates safety precautions during use.

- Dependence on Light Sources: The turntable operates solely on UV light or natural sunlight, limiting usability in low-light conditions.

Resiners Resin Curing Machine for Epoxy Resin Molds

For resin artists seeking efficiency and quality, the Resiners Resin Curing Machine (CURE AIR) stands out with its impressive 2-hour curing time. This auto-curing machine features a larger tray, accommodating various molds, and includes a winter preheating function that helps reduce bubbles. The transparent lid lets you observe the curing process, ensuring you’re always in the loop. Weighing only 2.2 pounds and measuring 13.3 x 10.21 x 6.3 inches, it’s compact yet powerful. Users rave about its performance and significant improvements in project quality, making it a valuable addition to your resin crafting toolkit.

Best For: Resin artists looking for a fast and efficient curing solution to enhance their crafting projects.

Pros:

- Fast Curing: Reduces curing time from 24 hours to just 2 hours, allowing for quicker project turnaround.

- User-Friendly: Simple setup and intuitive interface make it accessible for both beginners and experienced artists.

- High-Quality Results: Cured resin is crystal clear with a glossy finish, improving the overall quality of projects.

Cons:

- Limited Tray Size: Some users find the tray small for larger projects, which could restrict creativity.

- Heat Distribution Concerns: A few users have reported issues with heat distribution, potentially affecting curing quality.

- Stability Issues: Proper placement of the tray is crucial to avoid instability during the curing process.

Cure3 405nm UV Resin Curing Machine

Craft enthusiasts seeking a reliable and efficient solution will find the Cure3 405nm UV Resin Curing Machine an ideal choice. This 10.3-inch curing station features adjustable drying settings, allowing you to customize the timer from 0 to 15 minutes for optimal outcomes. With 360° all-side uniform curing and a built-in turntable, your projects receive even UV exposure. Safety is prioritized with a protective lid and case, ensuring you’re shielded from UV light. Plus, the activated carbon filter and purification fan manage odors effectively, creating a pleasant workspace. With a 4.5-star rating, it’s a popular option for serious crafters.

Best For: Craft enthusiasts and serious crafters looking for an efficient and reliable UV resin curing solution.

Pros:

- Adjustable drying settings allow for customization of curing times to achieve optimal results.

- 360° uniform curing with a built-in turntable ensures even exposure to UV light for all projects.

- Odor management system with an activated carbon filter and purification fan creates a pleasant work environment.

Cons:

- Limited size compatibility for larger 3D prints due to its maximum build size of 10.3 inches.

- Weight of 15.4 pounds may make it less portable for users needing to move it frequently.

- Price point may be higher compared to basic curing solutions on the market.

ELEGOO Mercury Plus 3.0 Wash and Cure Station for 3D Printing Models

Designed specifically for enthusiasts of 3D printing, the ELEGOO Mercury Plus 3.0 Wash and Cure Station excels in offering a seamless post-processing experience. With enhanced capacity and a 2-in-1 functionality, it cleans excess resin and cures your models efficiently. The powerful vortex cleaning and generous sizes—230 * 135 * 260 mm for washing and ∅250 * 290 mm for curing—ensure compatibility with popular 3D printers like Saturn and Mars. Plus, its 360° all-round curing with 24 LED lights guarantees even UV exposure. Safety features, including a sealed container and auto-pause function, make it a smart choice for any 3D printing project.

Best For: 3D printing enthusiasts looking for an efficient and safe post-processing solution for their resin models.

Pros:

- Enhanced capacity with a 114% increase in cleaning size and a 200% increase in curing size compared to previous models.

- 2-in-1 functionality allows for both cleaning and curing in a single process, saving time and effort.

- Safety features such as a sealed container and auto-pause function provide peace of mind during operation.

Cons:

- Larger footprint may require more space compared to smaller wash and cure stations.

- Limited compatibility with printers beyond the ELEGOO Mars/Saturn series and those up to 10 inches.

- Potential learning curve for users unfamiliar with the post-processing steps in 3D printing.

ELEGOO Mercury Plus 2.0 Wash and Cure Station

The ELEGOO Mercury Plus 2.0 Wash and Cure Station is an ideal choice for hobbyists and professionals alike, thanks to its dual-purpose functionality that seamlessly combines washing and curing in one compact unit. Measuring 5.16 x 3.54 x 8.66 inches and weighing 8.36 pounds, it fits easily in your workspace. With 16 UV lamp beads and a 360° rotating turntable, it guarantees quick and even curing. Users appreciate its effective cleaning and compatibility with various print sizes. While some note slower curing times, including an extra bucket can enhance the cleaning process, making it a fantastic value for your resin projects.

Best For: The ELEGOO Mercury Plus 2.0 Wash and Cure Station is best for hobbyists and professionals looking for an efficient and compact solution for washing and curing 3D prints.

Pros:

- Effective cleaning and curing capabilities comparable to ultrasonic cleaners.

- Great value compared to name brand alternatives, making it a cost-effective choice.

- Compatible with various print sizes, accommodating larger models or multiple prints at once.

Cons:

- Concerns about UV light safety, requiring additional precautions during use.

- Slower curing times reported by some users due to lower light intensity and turntable speed.

- Noise levels during operation may be higher than expected.

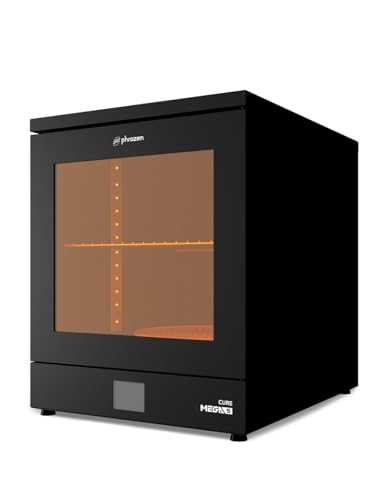

Phrozen Cure Mega S 3D Printer Resin Curing Station

If you’re a 3D printing enthusiast seeking efficiency and versatility, the Phrozen Cure Mega S 3D Printer Resin Curing Station is an excellent choice. It’s designed to cure photosensitive resin models with ease, featuring a UV light post lamp and a 360-degree transparent turntable. You can quickly select from multiple settings for drying and curing, making the process straightforward. The dual high-speed fans reduce drying time considerably, while the built-in interior light enhances visibility. Plus, the removable rack allows you to customize for larger models or multiple smaller ones, ensuring a seamless experience for all your 3D printing projects.

Best For: 3D printing enthusiasts looking for an efficient and versatile curing solution for photosensitive resin models.

Pros:

- Multiple settings for drying and curing, making the process user-friendly.

- 360-degree light source and transparent turntable ensure even curing of models.

- Removable rack provides flexibility for accommodating different model sizes.

Cons:

- May require additional space due to its size.

- Initial setup might be complex for beginners.

- Limited to photosensitive resin models, not suitable for other materials.

Factors to Consider When Choosing Resin Curing Stations

When you’re picking a resin curing station, there are a few key factors to keep in mind. Consider how well it works with your 3D printer, the speed and efficiency of the curing process, and its size and capacity. Don’t forget to check for safety features and a user-friendly interface to make your crafting experience smoother.

Compatibility With 3D Printers

Choosing a resin curing station that fits your 3D printer’s specifications is essential for achieving ideal results. Start by ensuring the station is compatible with your specific printer model, as many are designed for particular types like LCD, DLP, or SLA. Next, check the maximum build size capacity to accommodate the dimensions of your printed models; some stations can handle prints up to 10 inches tall or wide. Look for stations that support various resin types to enhance versatility across different projects. Additionally, verify that the washing and curing functionalities meet your printer’s requirements. Finally, consider adjustable height and basket features to effectively clean models of different sizes without compromising efficiency.

Curing Speed and Efficiency

After confirming compatibility with your 3D printer, the next key factor to evaluate is the curing speed and efficiency of the resin curing station. Curing times can vary greatly, with some stations curing models in as little as 10-15 seconds, depending on thickness and UV light proximity. Look for features like 360-degree rotating turntables that guarantee uniform exposure to all surfaces, enhancing the curing process. Advanced technologies, such as dual wavelengths in UV LEDs, cater to different resin types, improving overall performance. Stations with built-in fans can circulate air, expediting the drying process to mere minutes. Additionally, reflective designs can maximize UV light usage, boosting curing speed while minimizing energy waste. Choose wisely for the best results!

Size and Capacity Options

Size and capacity are essential factors to take into account for your resin curing station, as they directly impact the types of projects you can undertake. Curing stations vary in washing sizes, with maximum cleaning volumes ranging from 165 x 100 x 180 mm to larger options like 230 x 135 x 260 mm. Curing diameters can reach up to 250 mm, allowing you to handle bigger prints or multiple smaller models at once. Look for adjustable cleaning baskets, which enhance versatility for different print sizes, accommodating models from 5.9 inches to 10 inches and beyond. Also, consider the total cleaning bucket volume—some models offer up to 7.5 liters, making it easier to clean larger or multiple prints simultaneously.

Safety Features and Design

When selecting a resin curing station, it’s crucial to prioritize safety features and design elements that protect you during the curing process. Look for stations with UV-blocking lids and auto-pause mechanisms that activate when the cover is lifted, minimizing UV exposure. Sealed cleaning containers are also important, as they block UV light and reduce alcohol volatilization during washing. Choose stations equipped with safety switches and protective cases, allowing you to observe curing while being shielded from harmful UV light. Sturdy materials, like powder-coated metal, enhance durability and lower accident risks. Finally, make sure the station includes clear safety instructions to facilitate safe handling and operation, making your crafting experience both enjoyable and secure.

User-Friendly Interface

Choosing a resin curing station with a user-friendly interface can greatly enhance your crafting experience. Look for stations that feature simple one-click selections, allowing you to switch effortlessly between washing and curing modes. A clear display screen showing your settings and remaining time is essential for effectively monitoring the curing process. Intuitive controls, like rotary knobs for time adjustments, make it easy to set various curing durations without hassle. Additionally, prioritize safety features, such as UV-blocking lids and automatic shut-off when the lid is opened, which guarantee a safer operation. Finally, consider compact designs that fit seamlessly into your workspace, making it convenient to manage your 3D printing post-processing tasks without clutter.

Maintenance and Durability

A reliable resin curing station is essential for any crafting enthusiast, and its maintenance and durability are key factors to contemplate. When you’re choosing a station, consider the material; sturdy metal constructions often outlast plastic options. Pay attention to maintenance needs too; some stations require regular cleaning of UV light components for peak performance. Check user feedback on longevity—issues like detached control panels or fragile lids can be deal-breakers. Look for models that allow easy replacement of UV lamps or other components, as this can extend your station’s lifespan. Additionally, make sure the design offers easy access for cleaning, as this can help prevent resin build-up, ultimately enhancing usability and durability.

Price and Value Proposition

While evaluating resin curing stations, it’s essential to balance price and value. Prices vary considerably, with budget-friendly options around $120, while higher-end models may offer advanced features at a premium. Look for functionalities like dual washing and curing capabilities, which can replace multiple machines, saving you money over time. Additionally, consider the capacity; larger models can justify a higher price by accommodating bigger prints. Efficiency is also vital; stations that enhance curing uniformity and reduce time often provide better value. Finally, evaluate extra features such as safety mechanisms, noise levels, and user-friendly interfaces, as these can enhance your experience and justify investing in a more expensive curing station.